The example of Golden Jasmine Intimates Manufacturing

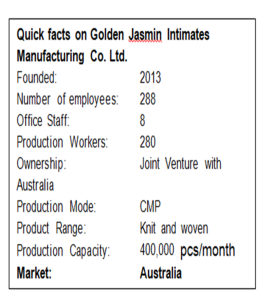

Golden Jasmine Intimate Manufacturing is a Myanmar-Australian joint venture owned by Mr. Douglas Edward Zappelic and Mrs. Moe Moe Lwin who is also the General Manager of the company. Their main products are pyjamas, track pants, T-shirts and other knit wear.

Golden Jasmine Intimate Manufacturing is a Myanmar-Australian joint venture owned by Mr. Douglas Edward Zappelic and Mrs. Moe Moe Lwin who is also the General Manager of the company. Their main products are pyjamas, track pants, T-shirts and other knit wear.

The company strives to expand its business with the EU and wants to work with retailers that are interested in shifting their sourcing operations from China to alternative markets.

Golden Jasmin values good social standards. It provides meals and accommodation to staff members who have migrated to Yangon in search for better jobs. The company has installed fire safety equipment and introduced occupational health and safety measures. Golden Jasmin is equipped with a large sample room, a warehouse and a well-organized finishing department.

Golden Jasmin participated in various SMART Myanmar trainings and

workshops. They took part in a study mission to Europe to visit relevant trade fairs, get information on social compliance and gather knowledge on changing the production mode from CMP to FOB1.

As part of the improvement program the company had fourteen consultation visits by the SMART Myanmar's SCP (Sustainable Consumption and Production) team. In ten of the visits, the SCP team was supported by international garment experts covering various topics.

ENHANCING PRODUCTIVITY

Production Planning and Cost Calculation

The management of Golden Jasmin was not familiar with variable and fixed costs which are the basis for a precise cost calculation and serve as a guideline for calculating production lead time and capacity planning.

SMART Myanmar arranged a workshop with international experts for “Calculations and costing in General” in December 2014 where Golden Jasmin wasn’t able to attend. The internal expert arranged a separate meeting with Golden Jasmin in their factory to share the information.

In order to get a complete overview of the production cost the management instructed the bookkeeping in-charge to compile the expenses of all departments for recalculating the cost of one production order and to gather data for future production orders to assure full coverage of Net Cost plus a profit percentage. The calculation was an eye-opener for the management as it revealed all expenses by category and percentage-wise distribution. As General Manager Mrs. Moe Moe Lwin put it: “I was impressed in learning the calculation scheme.”

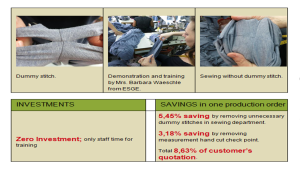

As part of the in-house consultancy on productivity improvements an assessment of production techniques and work flow was carried out on Golden Jasmin’s shop floor. Several unnecessary work steps while sewing a garment were identified which led to increased production time, higher cost and thus, decreased the profit of the company.

A demonstration for line supervisors and workers on how to construct the garment without using dummy stiches and hand cut check points was done by the expert. The staff were fast to learn and were wondering why they had put the stitches and check marks in the first place.

Using the newly introduced calculation scheme and the SAM (Standard Allowed Minutes) time study method the international expert calculated the cost of the current production by excludunnecessary work steps in the sewing department. The calculation showed potential savings and higher profits by producing in a more efficient way.

EFFICIENT USE OF RESOURCES

Energy Saving Measures

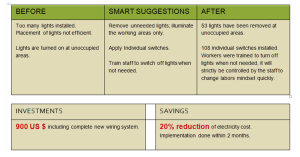

The production unit had sufficient lighting; lamps were even installed at unoccupied areas. Over each spread table three light panels were hanging and one more in-between the spread tables. Some lights were placed at workstations but in an inefficient way. One central light switch controlled the lighting of the entire shop floor instead of each department which led to waste of energy.

SMART Myanmar encouraged the management to decrease their consumption of valuable resources. As a quick action

example, SMART advised to remove lights at unoccupied areas and to install individual light switches to control each workstation separately. A further advice was to consider exchanging all lights with energy saving lamps such as LEDs. SMART also created a poster on ten “Energy Saving Tips” with many useful hints on how to save energy which was displayed in all departments. Most of the recommended energy saving measures require no financial investment.